Abstract

(1)Benefits of Ergothioneine

- Antioxidant

- Anti-aging

(2)Ergothioneine supplement dosage forms

- Capsule

- Tablets

- Powder

- Gummy

(3)Extraction methods

Ergothioneine production methods include natural biological extraction, chemical synthesis and biosynthesis. Currently, microbial fermentation in biosynthesis is considered to be the most promising large-scale industrial production method. Through genetic engineering technology, using modified Escherichia coli strains, batch fermentation in fermentation tanks can achieve efficient and stable production of Ergothioneine.

Article Content

Ergothioneine is mainly derived from fungi, certain bacteria and plants. It was first discovered in ergot (Claviceps purpurea), hence the name. In nature, mushrooms and some fungus-rich foods such as black fungus are important sources of Ergothioneine.

1. Antioxidant effect of Ergothioneine

Ergothioneine has strong antioxidant capacity both in vitro and in vivo. Its in vitro antioxidant effect is generally evaluated by detecting its ability to scavenge 1,1-diphenyl-2-trinitrophenylhydrazine free radicals, hydroxyl free radicals, etc., while its in vivo antioxidant effect is directly demonstrated by detecting biomarkers of oxidative damage in the body. The specific antioxidant mechanism includes the following four pathways: direct scavenging of ROS and reactive nitrogen, chelating divalent metal cations, stimulating the activity of certain antioxidant enzymes, and inhibiting the oxidation of heme proteins (heme and myoglobin, etc.).

2. Market prospects and product applications

Ergothioneine is suitable for use in soft capsules, tablets, powders, and soft candies. Due to its antioxidant and cell protection effects, it can also be integrated into beauty and skin care products. The Nue Co. has developed Ergothioneine Gummies containing Ergothioneine as part of their supplement line, offering antioxidant and cellular protection benefits.

Currently, Ergothioneine is popular in the United States, Japan and European countries, especially in the fields of anti-aging and immune support.

Ergothioneine has strong antioxidant and anti-inflammatory properties, and has significant effects on anti-aging and supporting the immune system. The demand for it is increasing worldwide. Especially in the fields of anti-aging, immune support and skin care, Ergothioneine is considered a potential ingredient. According to a report by market research company Grand View Research, the global antioxidant market is expected to continue to grow, which provides a broad market opportunity for emerging ingredients such as Ergothioneine.

3. Production technology

Ergothioneine is a high-value-added amino acid derivative with broad application prospects and unique biological functions. In particular, it has attracted widespread attention as an excellent antioxidant. Its preparation methods include natural biological extraction, chemical synthesis and biosynthesis. The current commercial production methods of ergothioneine mainly rely on extraction from natural organisms or chemical synthesis, both of which have problems such as high cost and low yield. Compared with other methods, the microbial fermentation method in the biosynthesis method has the advantages of low raw material cost, simple production process, safe, environmentally friendly and sustainable production, and is an ideal method for large-scale industrial production. However, the weak natural synthesis pathway and the difficulty in the coordinated supply of precursors histidine, adenosylmethionine and cysteine restrict the synthesis of ergothioneine. Therefore, it is urgent to develop an efficient, economical, safe and reliable ergothioneine production method to meet market demand, and researchers have made many attempts to this end.

4. Technical content

In view of the shortcomings of the existing technology, we constructed a genetically engineered strain of Escherichia coli for producing ergothioneine. The strain has systematically transformed the ergothioneine synthesis module, the precursor histidine, cysteine and adenosylmethionine synthesis module, and realized the efficient and stable production of ergothioneine in Escherichia coli, which belongs to the field of genetic engineering technology.

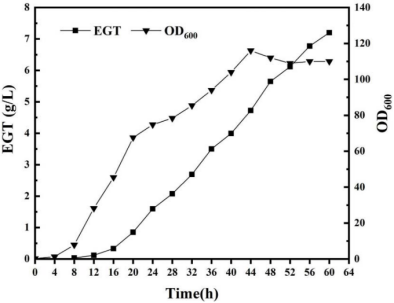

The genetically engineered bacteria in this technology use Escherichia coli as the host, heterologously overexpress the egtD gene from Microcoleus sp.PCC 7113, the egtB gene from Methylobacterium pseudosasicola, the egt2 gene from Neurospora crassa, the ATP phosphoribosyltransferase mutant encoding gene hisG* from Corynebacterium glutamicum; and overexpress the hisDBCHAFI gene cluster, the serine transacetylase mutant CysE (M201R) encoding gene, the phosphoglycerate dehydrogenase mutant SerA (H344A/N364A) encoding gene, and the adenosylmethionine synthase mutant MetK (I303V) encoding gene; and do not express the tryptophanase gene tnaA. Batch-fed fermentation was carried out in a 2L fermenter, and 7.2g/L of ergothioneine could be produced after 60h of cultivation, without significant accumulation of other by-products. The production volume and production intensity of the fermentation production method of ergothioneine in this technology are at the highest level reported so far, and no L-histidine and L-cysteine need to be added during the fermentation process, which can significantly reduce production costs.