Gummies are based on sugar, syrup, and various colloids, supplemented by appropriate amounts of vitamins (or minerals), natural animal and plant extracts, fruit juices, and other nutrients. After boiling and pouring, they are made into different shapes and textures. Nutritious gummies. Some gummies are sticky, some are brittle, some are transparent, some are translucent, and some are opaque.

The moisture content of gummies ranges from 7-24%, and the main feature is that it contains different kinds of colloids, which make the sugar body have gel properties, so it is also called gel candy.

According to different properties, gummies can be divided into different types.

1. Nutrition type

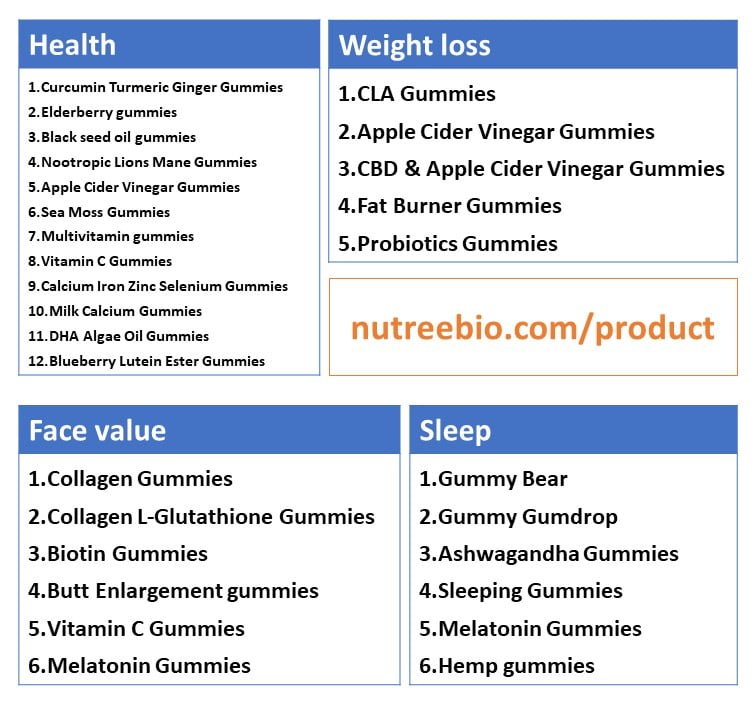

According to nutritional type, gummy can be divided into sleep series, immune and daily health care series, beauty series, and weight loss series.

The gummies of the sleep series:

- Gummy Bear

- Gummy Gumdrop

- Ashwagandha Gummies

- Sleeping Gummies

- Melatonin Gummies

Immunity and health care gummies:

- Curcumin Turmeric Ginger Gummies

- Elderberry gummies

- Black seed oil gummies

- Nootropic Lions Mane Gummies

- Apple Cider Vinegar Gummies

- Sea Moss Gummies

- Multivitamin gummies

- Vitamin C Gummies

- Calcium Iron Zinc Selenium Gummies

- Milk Calcium Gummies

- DHA Algae Oil Gummies

- Blueberry Lutein Ester Gummies

The gummies in the beauty serie:

- Collagen Gummies

- Collagen L-Glutathione Gummies

- Biotin Gummies

- Butt Enlargement gummies

- Vitamin C Gummies

- Melatonin Gummies

The gummies of the slimming series:

- CLA Gummies

- Apple Cider Vinegar Gummies

- Fat Burner Gummies

- Probiotics Gummies

2. shape type

Gummies come in raindrops (bullet), bears, raspberries, hearts, squares, diamonds, flamingos, and more.

- Raindrop type

Also known as the bullet shape, this is one of the most common shapes for gummies. The raindrop shape is suitable for gummies with natural animal and plant materials with special taste because the raindrop shape of gummies can add more sugar, and the sweetness can cover a part or neutralize it (special natural animal and plant materials) the taste. If you need gummies with less sugar, then we recommend against this option.

- Bear type

Gummy bears are one of the most popular gummies shapes in the world. The surface treatments of the bear-shaped gummies include sugar coating, waxing/varnish (Carnauba wax+MCT oil), and powder coating.

- Raspberry type

The surface treatment method of raspberry-type gummies can be made into sugar-coated, waxed/varnished, powder-coated, and other forms. Waxed raspberry gummies look very appetizing.

- Other shapes

Other common gummies shapes are hearts, squares, diamonds, flamingos, and more. Of course, if you have special shape requirements, you can contact us, and we can develop different molding molds according to customer needs.

3. Surface treatment

The surface treatment methods of gummies include powder coating, waxing, varnishing, and sugar coating.

Each treatment has its characteristics, such as powder coating that looks more grainy than sugar coating (granulated sugar), waxing and varnishing treatments that make the surface of the gummies shinier, and sugar coating treatments (granulated sugar) having a more sweet taste.

4. Basic colloid type

Gummies are named after the colloids used. The most basic colloids that makeup gummies are pectin, gelatin, carrageenan, etc.

- Pectin

Pectin gummy is made of white sugar, glucose syrup, pectin, and water as the main raw materials, and is processed into a gel candy with certain elasticity, and a soft and delicate taste.

Currently, among the gummies in the world, pectin gummies occupy a considerable proportion because pectin gummies have the advantages of soft texture, delicate structure, refreshing taste, and long shelf life.

The basic raw materials of pectin gummies are similar to other gummies, using granulated sugar, glucose syrup, flavor, coloring, and acid additives, the difference is that it uses pectin as a coagulant. Pectin is a polysaccharide, usually extracted from citrus peels and applesauce, which acts as strong intercellular coagulation in plants. As a natural source of plant colloid, pectin is an ideal raw material for making gummies, and it is easy to change and can make a variety of gummies with different tastes and flavors.

- Gelatin

Gelatin is the collagen contained in animal skins, bones, and tendons. Its main raw material is the skins of animals such as pigs, cattle, and sheep, which are then processed into gelatin after extraction and hydrolysis. The gelatin color is pale yellow or yellow. Gelatin can be used as the basic ingredient of gummies, soft capsule or capsule shells, etc.

Gelatin gummies use gelatin as the colloid. The moisture content is about 18-24%. The gummies made of gelatin are soft, elastic, bright in color, and have good transparency. The q-bomb chewiness is the biggest feature of gelatin gummies, and it is also the biggest difference from plant colloidal gummies. Due to the potential safety hazards of gelatin, the voice for replacing gelatin has been high. After a lot of raw material screening and formula debugging, pectin can also achieve a similar taste to gelatin. This not only avoids the hidden safety hazards of animal colloids but also greatly improves the temperature resistance, which perfectly solves the problems of high-temperature storage in summer and long-distance shipping.

- Carrageenan

Carrageenan is a polysaccharide gel extracted from red algae such as carrageenan. It dissolves in hot water and condenses into a transparent gel when cooled. After compounding, it can be used as a thickener, gelling agent, stabilizer, etc. Carrageenan is widely used in the modern food industry. The use of carrageenan originated hundreds of years ago. A kind of seaweed is produced on the southern coast of Ireland, commonly known as Irish Moss, now called Chondrus crispus, which is often collected, by residents. Boil the milk with sugar, let it cool, and solidify before eating. In the early 18th century, the Irish made this kind of seaweed into powder and introduced it to the United States. Later, a company began commercial production and began to sell it under the name of sea moss farina, which is widely used in milk and various foods. middle. In the 19th century, the United States began to refine carrageenan in factories, and it was not until the 1840s that the carrageenan industry developed in the United States. My country began to produce carrageenan on Hainan Island in 1973.

Carrageenan is a good coagulant. Carrageenan is the only protein-reactive colloid among natural colloids. It forms homogeneous gels with proteins. Carrageenan has the effect of dietary fiber and can replace the usual gelatin and pectin. The disadvantage of using gelatin is that the solidification and melting points are low, and low-temperature refrigeration is required for preparation and storage; the disadvantage of using pectin is that it needs to add high-soluble sugar and adjust the appropriate pH value to solidify. Carrageenan does not have these disadvantages. Carrageenan is not acid-resistant, and the acidity of carrageenan syrup causes the overall environment to be too acidic, and the acidity at a high temperature can easily destroy the colloid. Therefore, carrageenan is generally only used for sweet gummies.

Carrageenan also has shortcomings. Gummies powder based on carrageenan is not easy to dissolve under high sugar concentrations, and it is easy to produce "trachoma", that is, small rubber particles one by one.