How Gummies Are Made with Quality & Care.

GMP-certified manufacturing facility producing premium gummies for global brands.

✅ GMP, HACCP & ISO Certified Facility – Meeting the highest international supplement standards.

✅ Specialized in Gummies – Expert in functional gummy supplements for global brands.

✅ Global Reach – Products exported to 20+ countries across North America, Europe, and Asia.

✅ Full-Service Manufacturing – From R&D to large-scale production and packaging.

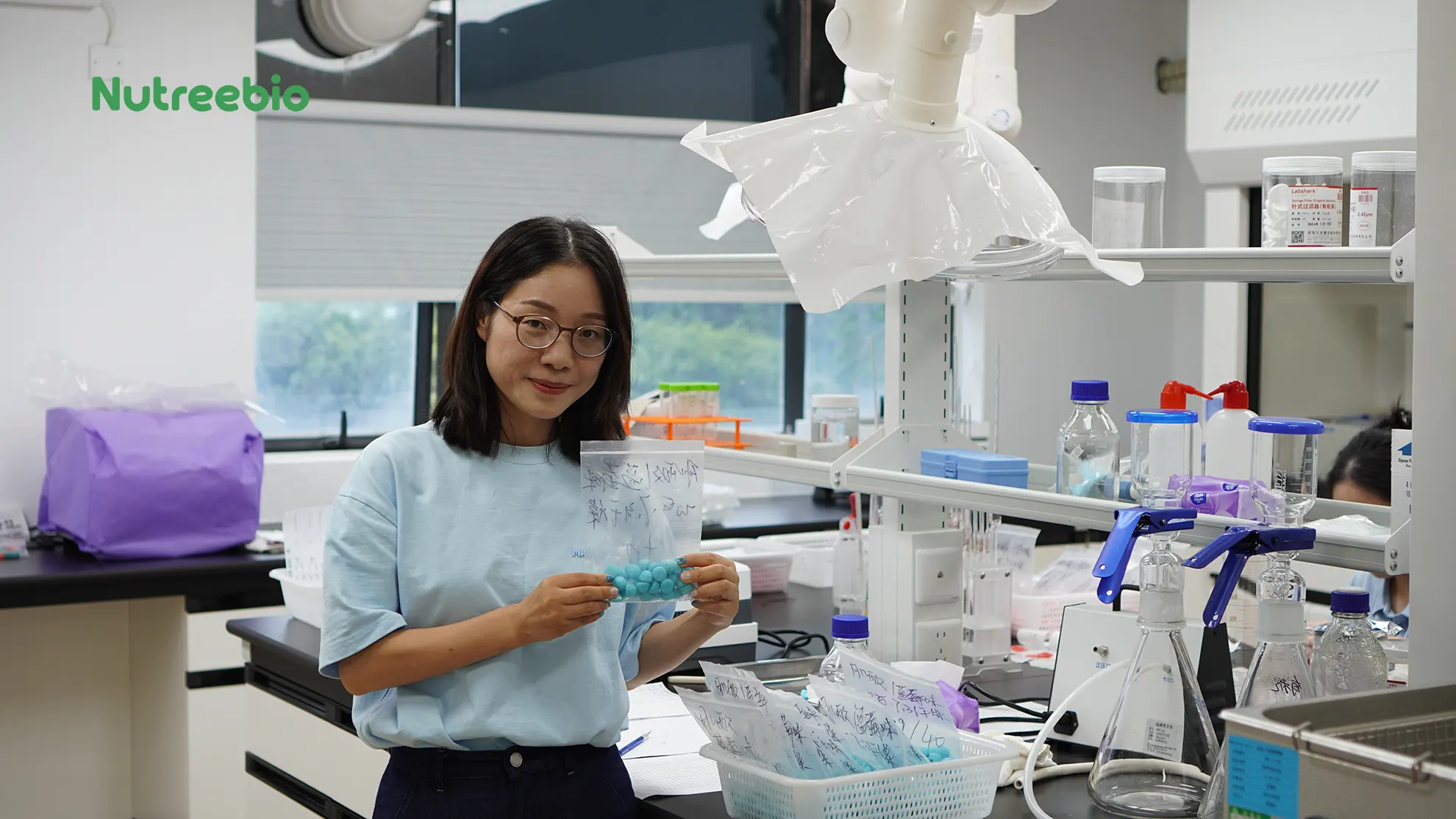

Our in-house R&D team works closely with clients to develop innovative gummy formulas, optimize taste and texture, and ensure regulatory compliance in target markets. We also offer small-batch sampling, stability testing, and flavor customization.

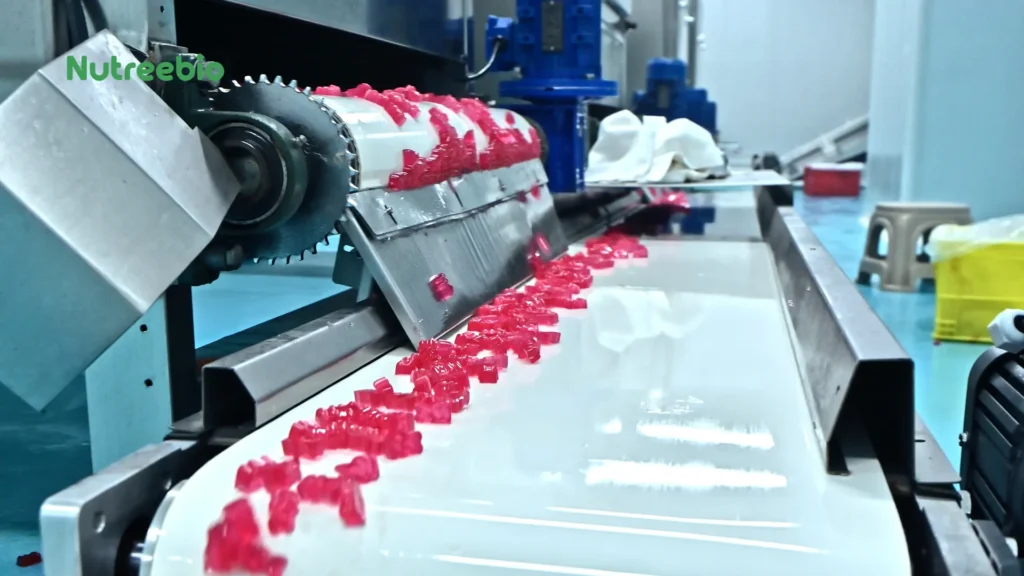

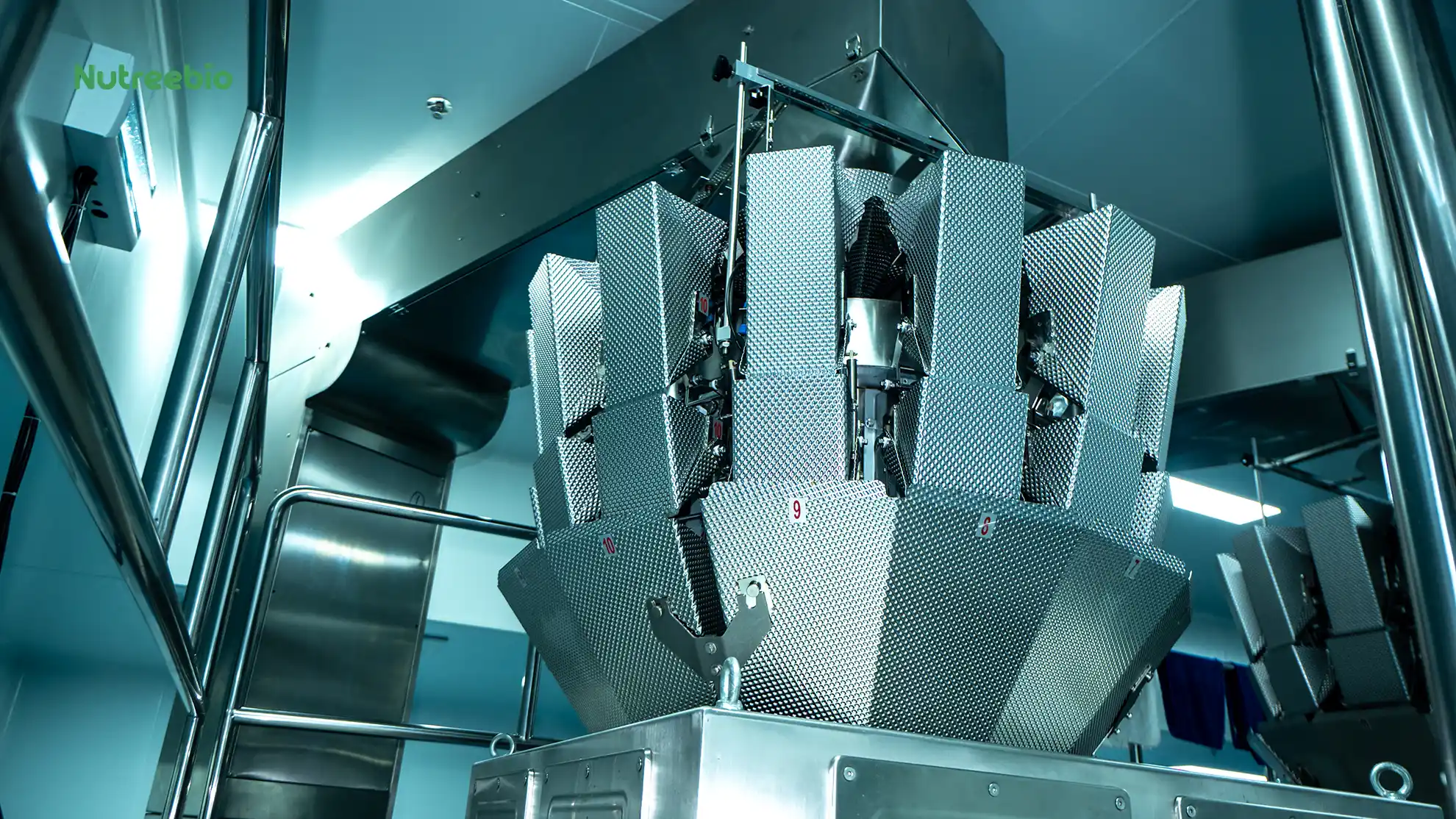

Our factory is equipped with advanced production lines dedicated to gummy manufacturing, ensuring consistency, efficiency, and scalability. Each production zone is designed for hygiene, safety, and efficiency, from ingredient preparation to final inspection.

Our in-house R&D laboratory enables us to create and refine custom formulations with precision. From ingredient selection to pilot batches, we ensure each gummy sample meets both functional and taste expectations before moving into full-scale production.

Every batch of raw materials is sourced from trusted suppliers and undergoes thorough quality checks for purity, potency, and safety. These raw materials are then placed in our warehouse.

Ingredients are precisely measured and cooked under controlled temperature and timing to ensure optimal consistency and nutrient retention.

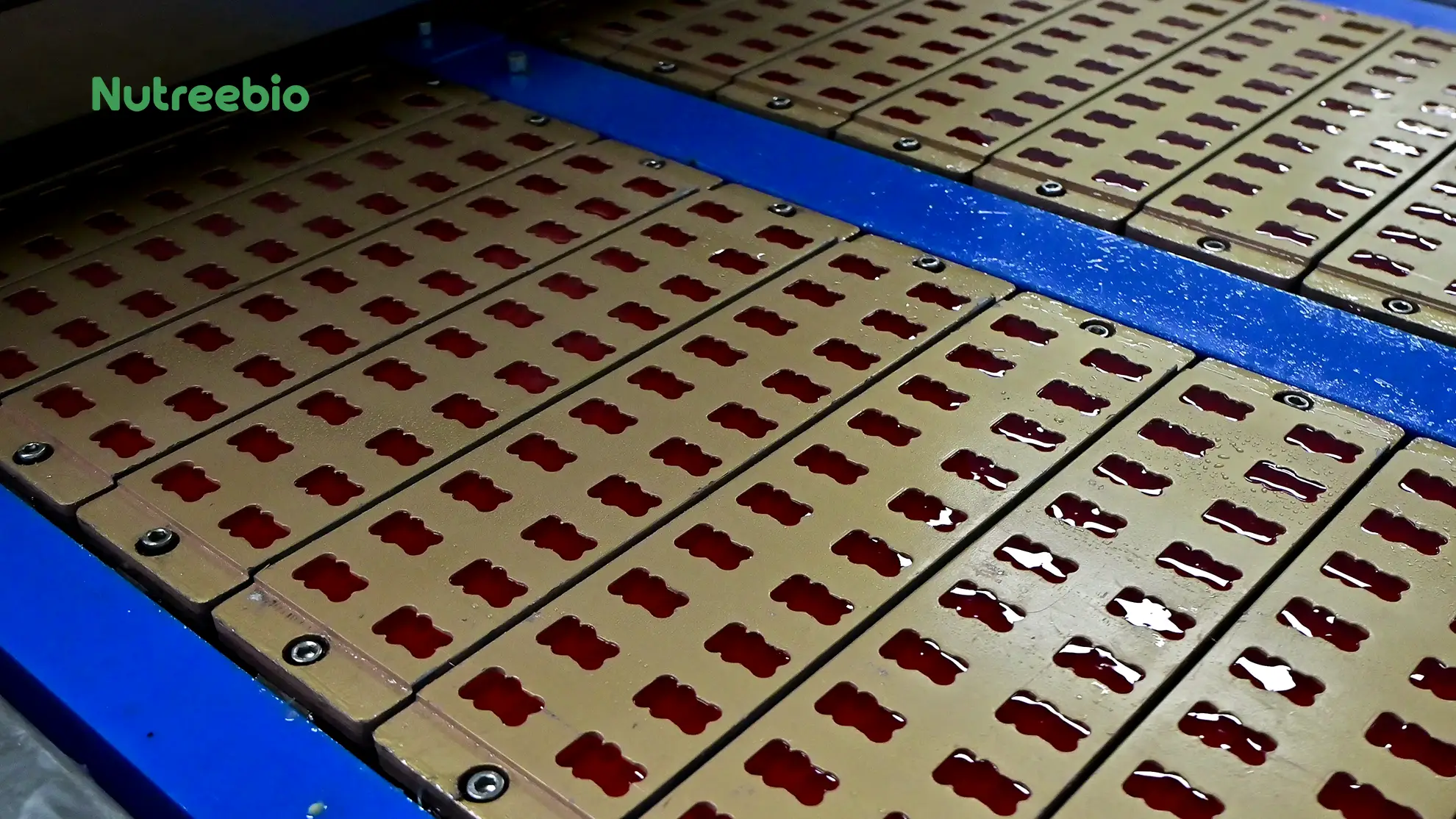

The gummy mixture is deposited into custom molds in various shapes and sizes, matching brand requirements.

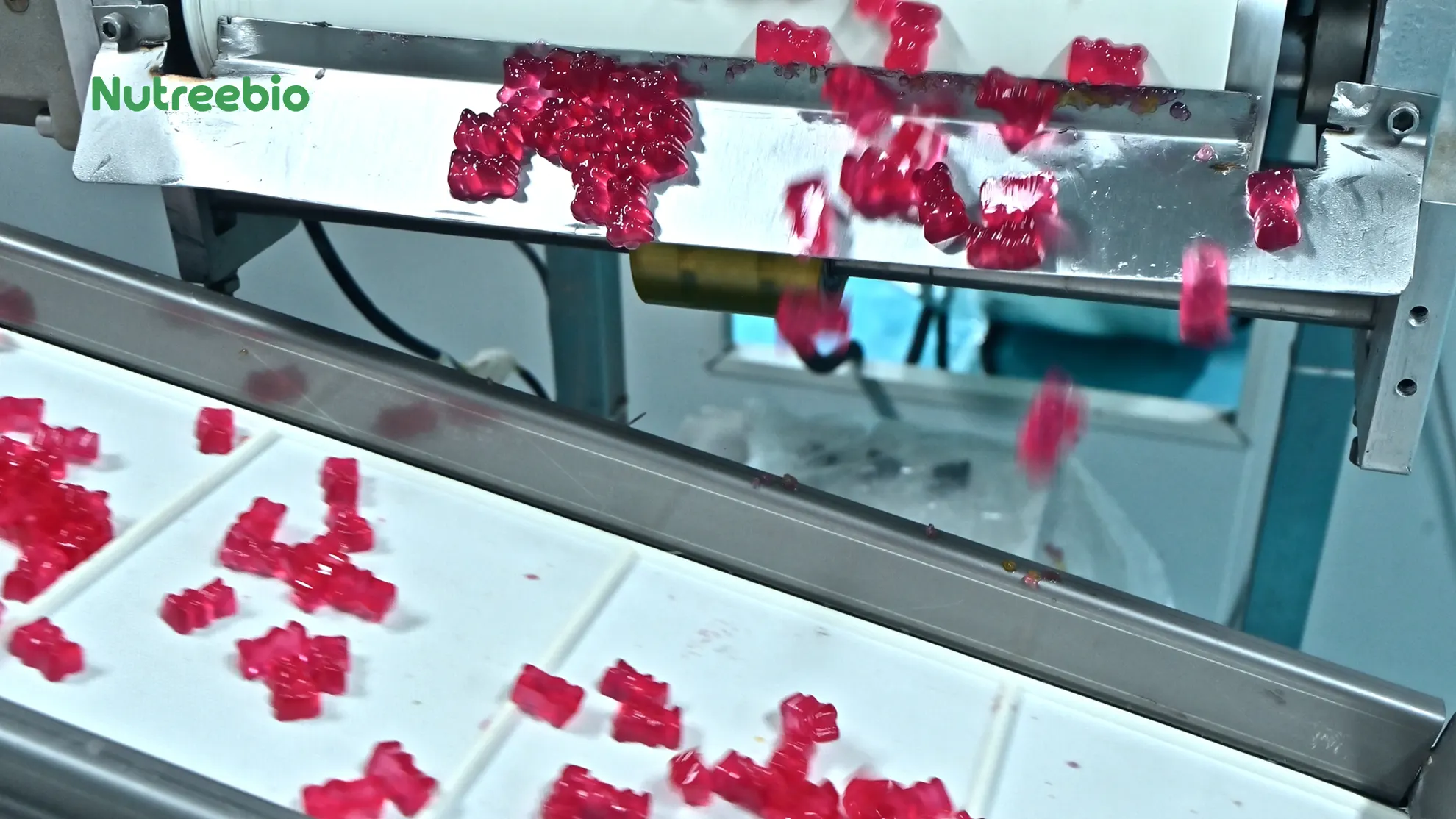

Once set, gummies are gently demolded and conveyed for further processing to maintain shape and texture.

Gummies are coated (if required) and undergo an initial drying process to improve stability and prevent sticking.

Controlled drying conditions ensure the perfect gummy texture, chewiness, and moisture content.

Gummies are polished for a clean, appealing appearance and uniform finish.

Finished gummies are counted, filled into bottles or pouches, sealed, labeled, and prepared for shipment.

Our climate-controlled warehouse ensures supplements are stored in clean, safe, and compliant conditions. Every batch is clearly labeled and tracked in our traceability system, ensuring product integrity until shipment.

We integrate sustainability into every stage of our supply chain. From responsibly sourced raw materials to state-of-the-art manufacturing equipment designed for energy efficiency, we minimize environmental impact without compromising quality. Our facilities use pure-water filtration and wastewater treatment systems to ensure safe discharge and protect local ecosystems. Every batch is fully traceable — from raw material sourcing to final delivery — meeting the strict requirements of major global regulatory authorities.

Once gummies pass final quality inspection, they are carefully packed in food-grade, tamper-proof packaging to ensure product integrity during transport. From production line to your warehouse, every step is handled with care and precision — ready to deliver your brand’s promise to customers around the globe.

Bottles, jars, pouches, or bulk cartons, tailored to your private label requirements.

Automated sealing and labeling lines ensure consistency and compliance with your target market regulations.

We coordinate with trusted freight forwarders to arrange sea, air, or express delivery worldwide, ensuring on-time arrival.

Ready to see your gummies come to life?

Contact us today to discuss your manufacturing needs and request a free sample.

Or call us at (+86) 18915905338

We will contact you within 1 working day, please pay attention to the email with the suffix “info@nutreebio.com”.

We’d love to hear from you! Send us a message using the form