If people used to enjoy gummies simply for their sweetness, today, gummies have evolved into a part of a healthy lifestyle. Functional gummies—also known as nutritional or dietary gummies—are rising rapidly around the world as a supplement that’s both delicious and beneficial. From Europe and the United States to Southeast Asia, and from children to seniors, people of all ages are seeking convenient and tasty ways to support their health. Especially now, with growing demand in areas like beauty, sleep support, and immune health, functional gummies are no longer just an upgraded candy—they’ve become a rising force in the nutritional supplement industry.

At Nutreebio, a foreign trade company specializing in the export of nutritional gummies, we've worked closely with multiple gummy manufacturing factories. Over the years, we’ve witnessed this category grow from a niche innovation into a mainstream standard among global health brands. In the early days, most customers came to us for simple, classic formulas—like children’s multivitamins or immune support. Today, the requests are far more complex and creative: from plant-based adaptogens and anti-glycation compounds to mood-supporting herbs. At the same time, customer requirements have become more specific—they want pectin-based, vegan, naturally colored, non-GMO, clean-label formulas that are not only effective but also social-media friendly, easily shared and embraced by younger consumers. In short, functional gummies today are part food, part supplement, and part marketing tool.

As the founder and manager of Nutreebio, I’m Kris. I’ve been working in the gummy business for nearly a decade. Over the years, I’ve had countless in-depth discussions with factory R&D teams, engineers, and production specialists. Gummies have become more than a product to me—they’re a part of my life. In this article, we’re not going to write another basic intro like “What are functional gummies?” nor simply copy-paste trends or statistics from abroad. Instead, we want to take you behind the scenes—from the perspective of a company deeply involved in gummy manufacturing—to show you how functional gummies are really made. We’ll break down the raw materials, processes, formats, regulatory aspects, market realities, and the hidden challenges behind these small but powerful products.

Our goal is simple: If you’re a brand owner, importer, wholesaler, entrepreneur, buyer, or even a nutrition R&D professional looking to develop your own line of functional gummies, this article will give you a comprehensive, real-world understanding of the category. You won’t need to spend time searching through scattered resources—we’ve condensed our experience, insights, and hard-earned lessons into one place.

The world of functional gummies is more complex than it looks—and more full of opportunity than most realize.

1. Definition and Classification of Dietary Gummies

In our factory’s production workshop, functional gummies and ordinary candies often run on the same production line—but their purposes couldn’t be more different. On one side, you have a treat meant to please the taste buds; on the other, a nutritional supplement designed to deliver health benefits. Though they may look alike, the two are worlds apart when it comes to formulation, ingredient selection, regulatory compliance, and quality control standards.

1.1 How Functional Gummies Differ from Traditional Candy

The main goal of traditional candy is simple: great taste. It’s all about vibrant colors, appealing flavors, and that chewy, satisfying texture that brings emotional comfort.

Functional gummies, on the other hand, are essentially a dosage form—a delivery system for active ingredients like vitamins, minerals, plant extracts, probiotics, collagen, melatonin, and more. The aim is to help consumers enjoy a tasty experience while also supporting their health in specific ways.

To put it simply:

Functional gummy = the taste of candy + the function of a dietary supplement.

But achieving both goals—great flavor and real efficacy—isn’t easy. It requires precision and expertise to strike that delicate balance.

1.2 Classification by Function

Most of the functional gummies on the market today are developed around a handful of high-demand health areas. These include:

- Beauty and skin health: collagen, hyaluronic acid, biotin, anti-glycation ingredients (e.g., L-cysteine)

- Sleep support: melatonin, L-theanine, valerian root extract, GABA

- Immune health: vitamin C, zinc, echinacea, elderberry, β-glucan

- Mood and stress relief: schisandra, St. John’s wort, ashwagandha, magnesium

- Children’s growth: multivitamins, calcium, DHA, lactoferrin

- Women’s health: evening primrose oil, cranberry, iron, folic acid

- Men’s health: zinc, maca, artichoke, ginseng extract

- Gut and metabolism support: probiotics, prebiotics, apple cider vinegar, inulin, green tea extract

These formulas often begin with a “single function” focus—this was how most of our early client projects started. But now, more and more brands are experimenting with multi-functional combinations such as:

- Whitening + antioxidant

- Sleep + stress relief

- Immune + digestive dual support

In our experience, functional classification based on health benefits is the most common and practical approach. That said, many clients also prefer to categorize their products by target demographic.

1.3 Classification by Target Consumer

The formula and positioning of a functional gummy will vary depending on the intended user. Common consumer segments include:

- Children: low-sugar or sugar-free, soft texture, added vitamins, calcium, DHA, etc. Formulations must strictly comply with children's dosage limits.

- Adults: broader functional needs, with a focus on anti-aging, mood balance, and weight management.

- Middle-aged and seniors: prioritize bone health, cardiovascular support, and vision care, with stricter sugar controls.

- Pregnant and nursing women: focus on safety and nutritional synergy, such as iron, calcium, folic acid, and DHA. It’s crucial to avoid restricted ingredients and ensure precise, compliant dosing.

Each consumer group comes with its own formulation priorities and regulatory considerations, especially for international markets. That’s why we take extra care when customizing formulas for export.

2. The Core of Nutritional Gummies: Raw Material Selection and Dosage Form Design

The biggest difference between making Nutritional gummies and regular candy is that you must strike a delicate balance between taste and effectiveness. While this might sound simple, it’s actually one of the most difficult aspects of product development. That’s because once active ingredients are introduced, they often bring bitterness, fishy notes, astringency, or metallic flavors, and can even interfere with the gummy’s structure or appearance.

That’s why choosing the right base ingredients and delivery format is the very first step that determines a gummy’s success or failure.

2.1 Pectin vs. Gelatin: Best Gelling Agents for Gummy Supplements

In the gummy world, the gelling agent is the foundation. The two most commonly used bases are gelatin and pectin—each with its own characteristics.

Gelatin-Based Gummies

- Source: Animal collagen (e.g., hydrolyzed bovine bones, pig skin)

- Pros: Soft and elastic texture, well-established processing, lower cost

- Cons: Not vegetarian, not heat-resistant, prone to melting

- Use Cases: Often used for children’s vitamins or candy-like vitamin C gummies

Pectin-Based Gummies

- Source: Natural plant-based, typically extracted from apple or citrus peel

- Pros: Vegan-friendly, firmer texture, better heat stability

- Cons: Higher cost, more complex process, sensitive to pH and sugar-acid ratio

- Use Cases: Preferred in exports to Europe, the U.S., and Southeast Asia; ideal for clean label products

At present, we almost exclusively produce pectin gummies, and we strongly recommend them to clients. As global demand grows for plant-based, sustainable, and clean-label products, pectin-based formulations have become the international standard.

2.2 Gummy Flavoring, Coloring, and Sweeteners

Whether a gummy is accepted by consumers often comes down to the first bite. However, formulas containing plant extracts, minerals, or vitamins often carry bitter, metallic, or earthy tastes. Flavor masking and balance are major challenges in development.

Gummy Flavoring

We primarily use natural flavors derived from fruits such as citrus, strawberry, apple, blueberry, and grapefruit. These not only enhance the overall taste but help cover undesirable notes from functional ingredients.

Natural Coloring Agents

- Purple cabbage powder – provides bluish purple

- Beetroot powder – provides red

- Gardenia yellow – provides bright yellow

- Carotene – gives an orange hue

- Sodium copper chlorophyllin – offers green tones

Sweetening Systems

Sweeteners vary depending on market preferences. Here’s a breakdown:

Sugar-Based (Traditional Sweet Gummies)

- Sucrose: Standard sweetness, natural taste, but high in calories and may cause tooth decay

- Glucose syrup: Less sweet than sucrose, helps retain moisture, but still high in calories

Conventional sugar has great taste and low cost, but we usually avoid recommending it to health-focused or export-oriented clients due to its high calorie content.

Sugar Alcohols (Low-Sugar Gummies)

- Erythritol: ~70% the sweetness of sucrose, low calorie, non-glycemic

- Xylitol: Similar to sucrose, protects teeth, but excess may cause digestive discomfort

- Maltitol: ~90% sweetness, low calorie, but may lead to bloating

- Isomalt: ~50% sweetness, low calorie, stable and non-glycemic

This type of sweetener is our most commonly used base. A combination of maltitol + isomalt is particularly effective for sugar-free formulations, delivering a balanced taste with minimal impact on blood sugar—perfect for health-conscious consumers and export markets.

Natural Sweeteners (Zero-Sugar Gummies)

- Stevia: 200–300x sweeter than sucrose, zero calories, diabetic-friendly

- Monk fruit extract: 150–200x sweetness, also zero calorie

Natural sweeteners are ideal in theory, especially for diabetic-friendly claims. However, in real-world production, it’s challenging to achieve a “perfect” natural-sweetener gummy due to aftertaste and formulation issues. Still, we often add a small amount to fine-tune flavor in sugar-free recipes.

In short: Taste, color, and aroma must work together to mask functional ingredients and attract repeat purchases.

2.3 Gummy Ingredients: Key Active Components in Functional Gummies

The “function” in functional gummies all comes down to what active ingredients you include. These are typically:

- Vitamins: C, D, B-complex, E – found in many general wellness formulas

- Minerals: calcium, zinc, iron, magnesium – common in kids’, women’s, and senior supplements

- Plant Extracts: echinacea, ashwagandha, bitter orange, gotu kola, St. John’s wort, apple cider vinegar

- Proteins/Amino Acids: collagen peptides, cysteine, GABA, L-theanine

- Fiber & Fungi-Based: probiotics, prebiotics, FOS, inulin, β-glucan

These are the ingredients most valued by our clients—but more is not always better. It’s critical to control dosage carefully.

Typical guideline:

Functional ingredients should generally account for no more than 10% of the total formula, and absolutely no more than 20%.

Exceeding that can result in:

- Molding issues (won’t set properly or turns sticky)

- Off-colors or unpleasant odors

- Bitter or harsh taste that hurts consumer acceptance

When the gummy tastes “off,” it loses one of its biggest advantages. That’s why “higher dose = better effect” doesn’t apply here. Sometimes, we solve the dosage challenge by adjusting the process or designing multi-gummy dosing regimens—this is an area we're continually improving.

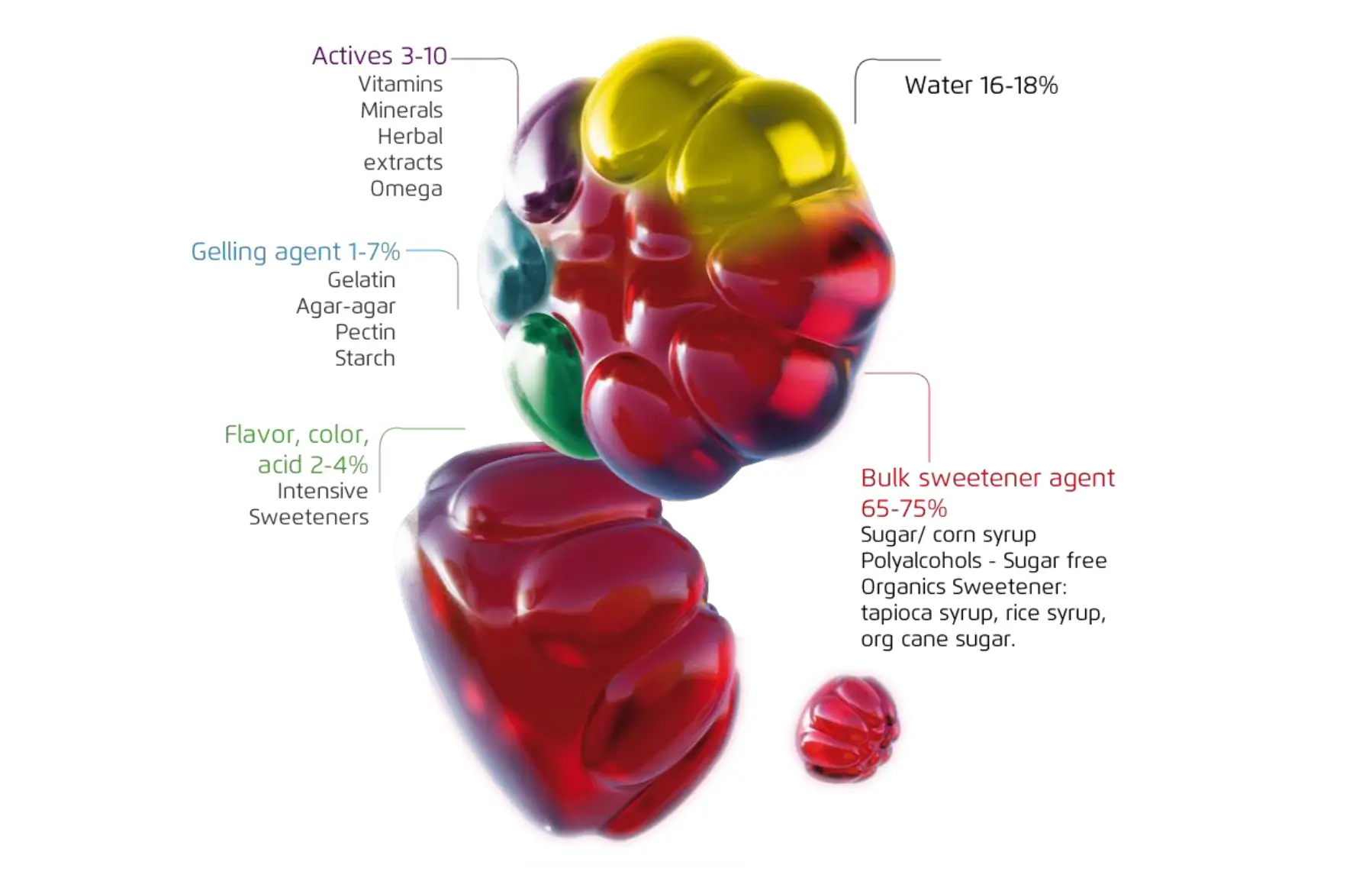

2.4 Other Gummy Ingredients: Basic Formulation Reference

Aside from active components, every gummy also relies on a set of foundational ingredients to hold everything together. Here’s a breakdown of the typical ingredients and their roles:

| Ingredient Name | Function | Typical Proportion |

|---|---|---|

| Isomalt | Sweetener (low-calorie sugar alcohol) | 15–30% |

| Maltitol | Sweetener (sugar alcohol) | 10–25% |

| Pectin | Gelling agent, provides structure | 1.5–2.5% |

| Citric Acid | Acidity regulator, enhances tartness | 0.3–0.5% |

| Sodium Citrate | pH stabilizer, supports gel consistency | 0.1–0.3% |

| Natural Flavor | Adds taste, masks bitterness | 0.2–1% |

| Natural Coloring | Adds color, improves appearance | 0.05–0.3% |

| Coconut Oil | Anti-sticking agent (sprayed) | 0.2–0.5% |

| Carnauba Wax | Surface coating, anti-stick, adds shine | 0.1–0.3% |

These ingredients may only make up a small portion of the formula, but each one plays a crucial role. If the ratios are off, you may run into product issues like stickiness, cracking, sourness, bitterness, or melting.

3. Regulations and Certification: Can Functional Gummies Truly Go Global?

“This gummy sells really well in Europe—can we launch it in the U.S. too?”

“The customer said this formula doesn’t comply in the UK—is it because the vitamin C content is too high?”

“Is melatonin restricted in the Philippines?”

These are the kinds of questions I answer almost every day.

If you want to bring functional gummies to the global market, it's not as simple as translating your label and shipping overseas. Behind every successful launch lies a complex web of regulatory systems, ingredient restrictions, and claim limitations that vary widely from country to country.

At the same time, more and more of our clients—brand owners, distributors, and e-commerce platforms—are demanding clearer label claims and stricter product certifications. What may appear to be “just a marketing label” is often, in reality, your ticket to market access.

3.1 Overview of Regulatory Systems in Key Markets

United States (FDA / DSHEA)

In the U.S., functional gummies are typically categorized as dietary supplements and regulated under the Dietary Supplement Health and Education Act (DSHEA):

- Must comply with GMP (Good Manufacturing Practices)

- Ingredients must be listed as GRAS (Generally Recognized As Safe) or require an NDI (New Dietary Ingredient Notification)

- Functional claims are limited to structure/function statements and cannot imply disease treatment

No pre-market approval is required, but once on the market, FDA may audit or test products and require full documentation

European Union (EFSA)

The EU takes a more stringent approach to food supplements:

- All ingredients must be reviewed and approved by EFSA (European Food Safety Authority)

- Claims must be pre-approved under the EU Register of Health Claims, with wording strictly regulated

- Maximum intake levels are defined for vitamins, minerals, and botanical ingredients

- Emphasis is placed on consumer safety and transparency

Australia (TGA)

In Australia, gummies are often regulated as complementary medicines by the Therapeutic Goods Administration (TGA) and must be registered (AUST L / AUST R):

- Every ingredient must be listed in the ARTG (Australian Register of Therapeutic Goods)

- Functional claims must be supported by scientific literature

- Products that don’t meet therapeutic guidelines must be sold as food and follow food regulations instead

Philippines (FDA Philippines)

Functional gummies are regulated as food supplements under the Philippine FDA:

- All products require a Certificate of Product Registration (CPR)

- Claims like “boosts immunity,” “antioxidant,” and “nutritional support” are allowed

- Any language implying disease treatment is strictly prohibited

✅ Kris’s advice: Always consult a regulatory professional to verify ingredient legality, dosage limits, and label claims before launching in any new market. One formula cannot serve every country. At Nutreebio, we provide localized formula versions tailored to each region’s compliance needs.

3.2 Clean Label Trends and Challenges

As consumers demand more transparency, natural ingredients, and sustainability, the global gummy market has entered what we call the "clean label era." This isn’t just a trend—it’s quickly becoming a minimum requirement for international success.

3.2.1 Common “Clean Label” Claims (Frequently Requested by Clients)

| Label Type | Definition | Consumer Relevance |

|---|---|---|

| Vegan / Plant-Based | No animal-derived ingredients | Appeals to vegetarians and ethically conscious consumers |

| Non-GMO | Free from genetically modified organisms | Perceived as safer and more natural |

| Gluten-Free | No wheat, rye, or barley gluten | Safe for gluten-sensitive individuals or celiac patients |

| Sugar-Free / No Added Sugar | No sucrose or sugar added | Ideal for diabetics and low-GI diet followers |

| Dairy-Free / Lactose-Free | No milk-derived ingredients | Suitable for those with lactose intolerance or dairy allergy |

| Nut-Free / Soy-Free | Free from nuts and/or soy | Prevents allergic reactions |

| No Caffeine / No Stimulants | Contains no stimulants like caffeine | Safe for children, pregnant women, and nighttime use |

| Organic / Fair Trade | Naturally grown without pesticides/fertilizers | Appeals to premium market and environmentally aware consumers |

| Keto / Paleo | Fits special dietary lifestyles | Popular among fitness or low-carb communities |

| Cruelty-Free | No animal testing involved | Important for ethically-driven consumers |

| All-Natural / No Preservatives / No Artificial Additives | No synthetic ingredients | Builds consumer trust in product purity and safety |

3.2.2 Certification & Declaration Support

| Certification Type | Applies To | Common Examples |

|---|---|---|

| Product-Level | Finished gummy products | - COA (Certificate of Analysis) - Non-GMO Declaration - Allergen-Free Certification - Vegan / Organic Certificates - Stability Reports - Microbiological, heavy metal, and nutritional content testing |

| Factory-Level | Manufacturing facilities | - GMP (Good Manufacturing Practice) - ISO 22000 / ISO 9001 / ISO 45001 / ISO 14001 - HACCP Certification - FDA Registered Facility (for U.S. exports) - Halal / Kosher Certifications |

| Raw Material-Level | Active ingredients/sourcing | - Vegan / Organic / Halal / Kosher declarations for raw ingredients - Non-GMO origin certificates - Supply chain traceability and Fair Trade documentation |

These certifications and claims don’t just build consumer trust—they’re increasingly essential for cross-border logistics, online platform entry, and retail distribution.

For example, in Europe and North America, gummies without Vegan or Non-GMO declarations often fail to pass initial screening by mainstream distributors.

In Summary, Regulatory compliance and certification are the foundation for selling functional gummies internationally. When designing a formula, our factory considers not just feasibility and cost—but also regulatory paths and label strategy from day one. It’s this kind of forward planning that enables a gummy to succeed in markets around the world.

4. The Birth of a Gummy: A Factory’s Perspective

Many people assume that making gummies is just like making candy: boil some syrup, add flavor and color, pour it into a mold, and you’re done. But from a factory’s perspective, the birth of a functional gummy is a systematic process involving cross-disciplinary collaboration, interdepartmental coordination, and meticulous control.

From an idea scribbled on paper to a finished product on the shelf, each gummy embodies the intersection of science, technical expertise, and market insight.

4.1 Initial Request: Starting with a Concept

It all typically begins with a customer’s request:

“I want to create a whitening gummy for young women.”

“Can you add something to help with sleep? My customers struggle with insomnia.”

Once a concept is proposed, our work begins. The first step is to clarify the functional goal, target market, consumer group, and flavor preferences. At the same time, we ask key questions such as:

- What is the intended export market (e.g., U.S., EU, Southeast Asia)?

- Are there specific formula constraints (e.g., vegan, sugar-free, clean label)?

- What is the desired look, color, taste, and packaging format?

At this stage, we collaborate with the factory's R&D team to develop a preliminary product positioning plan.

4.2 Formula Development: Nutritionists and Food Engineers in Tandem

The heart of gummy development lies in formula modeling. It’s not about mixing random ingredients—it’s about finding an optimal solution that balances regulatory requirements, taste, stability, cost, and ingredient ratios.

We typically follow a dual-development system involving:

- Nutritionists, who handle the functional design and scientific dosage references (e.g., melatonin ≤ 3mg; hyaluronic acid recommended at 30–60mg)

- Food engineers, who assess whether ingredients are compatible with the gummy base (e.g., certain minerals may interfere with gelling). Factors such as pH, sweet/sour balance, gum type, and sensory experience are considered early in the prototyping process.

4.3 Ingredients & Dosage Guidelines: Compliance Comes First

You can't just add any ingredient into a gummy and assume it's good to go—different countries have strict rules on what’s allowed, how much can be used, and what claims can be made.

Take melatonin as an example:

- USA: Allowed (2–10mg), but cannot claim to “treat insomnia”

- EU: Not permitted in conventional foods

- Philippines: Considered a drug and not allowed in supplements; however, “immune support” claims are accepted

That’s why we customize formulations by region, ensuring each product is both effective and legally compliant.

4.4 Matching Active Ingredients with Excipients

A great formula isn’t just about what's in it—it’s about how well everything works together. Excipients play a crucial role in supporting flavor, texture, and stability.

Here’s how we match them:

- Sweeteners: Choose from sucrose, glucose syrup, sugar alcohols (Isomalt, Maltitol), or natural sweeteners (stevia, erythritol) based on function and market demands

- Gelling agents: Pectin or gelatin, based on desired texture and dietary claims

- Flavors & colors: Natural flavorings (orange, cherry, grape) and natural pigments (beet red, beta-carotene, etc.)

- Acidity regulators: Citric acid and sodium citrate to stabilize pH and enhance taste

- Anti-sticking treatments: Oiling, sugar coating, or wax spray to keep gummies from clumping

These so-called “supporting ingredients” are essential to make the gummy pleasant to eat and appealing to look at.

4.5 Sample Iteration: The Precision Work of Gummy Development

After the first prototype, we go through several rounds of fine-tuning based on client feedback:

- Is the color too dark?

- Does the flavor taste natural?

- Is the texture too hard or too soft?

- Are there off-flavors from the active ingredients?

- Are there stability issues like stickiness or weeping?

We even simulate export conditions (heat, humidity, movement) to assess shelf stability.

A basic sample round takes 3–5 days; more complex projects may require 4–8 rounds of revisions over 1–3 months.

4.6 Production Flow Overview

Here’s a typical production flow for functional gummies:

- Ingredient Preparation: Accurately weigh syrup, gelling agent, acidity regulators, flavors, colors, and actives

- Heating and Mixing: Blend at high temperature until fully dissolved

- Vacuum Degassing: Remove air bubbles to prevent holes

- Molding: Pour into molds to begin solidification

- Cooling & Drying: Move to drying room; drying time varies (pectin: 24–48h, gelatin: 6–12h)

- Demolding & Surface Treatment: Apply wax, powder, sugar coat, or oil

- Quality Check & Weighing: Evaluate appearance, weight, and sensory characteristics

- Packaging: Bottle, bag, or box according to client specifications

For a deeper dive, see our detailed manufacturing article here: [Mastering Gummy Production: Ingredients, Processes, and Quality Standards]

4.7 Quality Control: Every Batch Gets a Check-Up

Before leaving the factory, each batch goes through rigorous testing by our QC team:

- Physicochemical testing: Moisture, pH, gel strength

- Microbiological testing: Total plate count, coliforms, mold, yeast, Staph. aureus

- Heavy metal testing: Lead, arsenic, mercury, cadmium

- Sensory analysis: Color, aroma, taste, appearance

- Nutrient analysis: Vitamin levels, actives like melatonin, collagen, probiotic viability

Each shipment comes with a Certificate of Analysis (COA) and batch number for full traceability—from raw material to final product.

4.8 Additional Customization Options

Beyond formulation and testing, customization also includes appearance, surface finish, and packaging.

✅ Common Gummy Shapes (Molds Available)

We currently offer over 10 standard mold shapes, and custom molds can be created upon request:

- Bears

- Large Bear

- Berry

- Apple

- Star

- Half Round

- Flower

- Dome

- Cube

- Button

✅ Surface Treatments

- Wax Coating: Beeswax or carnauba wax for anti-stick and shine

- Sugar Coating: Erythritol coating for added texture and taste

- Powder Coating: Light starch dusting, often used in fruit-flavored gummies

- Oil Coating: Rarely used; sometimes seen in low-sugar formulations

✅ Packaging Formats

- Bottles: PET bottles, clear or opaque, most commonly 60 gummies

- Jars: Shorter, wider containers, often for 120–150 pieces

- Pouches: Stand-up zipper bags, ideal for 100–200g bulk packs

- Individual Sachets: 5–10 pieces per pouch, convenient for single use

- Paper Tubes: Unique packaging for gifting or premium positioning

- Color Boxes: Bottles paired with printed cartons for retail or online display

✅ Packaging Information

- Expiration Date: Typically 2 years, e.g., EXP DATE: 2026-07

- Batch Number: Used for traceability and quality control

What may look like a simple gummy is actually the result of dozens of decisions made at every stage—from formulation and regulation to production and packaging.

Manufacturing is only one part of the story. Behind every successful product lies a full-stack team—a technical think tank and quality assurance system—working quietly behind the brand.

5. Common Misunderstandings to Watch Out For (FAQ)

Since functional gummies became a hot trend—especially in the past few years—I’ve met many clients who, after looking at the data on popular products, excitedly say things like:

“I want to make a high-dose formula!”

“I want to add ten active ingredients!”

“I want to create the most complete gummy on the market!”

But when it came time to actually produce the product, the reality hit:

“The idea was grand—but the execution, not so much.”

As a frontline factory, we battle with formulation challenges daily. In this section, I’ve compiled some of the most common misunderstandings, along with practical tips based on real-world experience. Hopefully, this helps you avoid unnecessary detours when developing your product.

❌ Question 1: Can I just pack my gummy with high-content actives? The more, the better, right?

Our answer: Not really.

Many clients start out saying,

“Let’s go bold—200mg of hyaluronic acid, 300mg of glutathione, 100mg of vitamin C. The higher the content, the stronger the selling point.”

But here’s the reality: such formulas often can’t be manufactured successfully.

Why?

- Gummies are a semi-solid matrix, and every ingredient you add affects the final texture, gelling process, and drying behavior.

- When active ingredients exceed 10% of the total formula, problems arise: off-flavors, poor texture, molding issues, discoloration.

- High-dose actives often taste bad—iron, zinc, glutathione, collagen, melatonin—they bring bitterness, fishiness, astringency, or a metallic aftertaste.

Factory tips:

Keep total active content within 10%, max 20%.

Use "2 gummies/day" or "3 gummies/day" dosing to reach your intended daily value.

Focus on scientific dosage planning + multi-gummy recommendations—don’t try to squeeze the whole world into a single gummy.

❌ Question 2: Can I just combine all trending ingredients into one “super gummy”?

Our answer: Technically yes—but we don’t recommend it.

Functional gummies aren’t like superfoods—“the more you take, the better.” While multi-benefit formulas (e.g., whitening + antioxidant + anti-glycation) are becoming more common, cramming too many actives into one gummy presents serious challenges:

(1) Ingredient Compatibility

- Some ingredients interact poorly. For example, vitamin C and metal ions can neutralize each other.

- Probiotics are sensitive to acidic environments and may not survive alongside fruit acids.

- Strong flavors (e.g., vanilla or apple cider vinegar) can dominate and throw off the overall taste.

(2) Absorption Differences

- Fat-soluble and water-soluble vitamins don’t absorb well in the same matrix.

- Some ingredients should be taken with meals, others before bed.

- Clashing metabolic pathways reduce overall bioavailability.

(3) Regulatory & Labeling Issues

- Too many functions make it hard to clearly position the product.

- In the EU and US, labels cannot use terms like “treatment” or “all-in-one solution”—doing so could violate regulations.

✅ Factory Advice: How to Build a Smart Multi-Active Gummy

- Limit active ingredients to 3–5 maximum

- Each ingredient should have a clear purpose and justified dosage

- Focus on synergistic combinations, like: Collagen + vitamin C, Probiotics + prebiotics, Melatonin + theanine

- Pay attention to stability, pH compatibility, and flavor harmony

- For multi-functional products, always provide dosing guidance (e.g., 2 gummies per day, after meals)

💡 Case Study: Whitening Gummy Formulation

One of our past projects involved a client requesting a 3-in-1 gummy for whitening, antioxidant, and anti-glycation effects. After thorough discussion between myself, our sales manager Nicole, and the client, we finalized the formula as follows:

- Glutathione – 50mg

- Hyaluronic Acid – 30mg

- Vitamin C – 60mg

- L-Cysteine – 30mg

Suggested use: 2 gummies daily, with meals

Flavor: Lychee-flavored pectin-based gummy, with a soft, bouncy texture and rich fruit aroma

Surface treatment: Coated with Brazilian carnauba wax to prevent sticking and improve visual appeal

Thanks to careful dosage control, flavor masking, and gum base optimization, the final product was well-balanced in function, taste, and compliance.

✅ Final Thoughts

A great functional gummy isn’t built by throwing in as many ingredients as possible—it’s built through scientific design.

We recommend that every brand work closely with our team at the product planning stage. By thinking holistically across market demand, regulatory compliance, flavor design, and technical feasibility, you’ll avoid common pitfalls and build a gummy that truly sells well and tastes great.

If you’re considering launching a functional gummy, I suggest bookmarking this “gummy development guide”. These insights are all based on real experience. Of course, if anything’s missing or unclear, we’d love your feedback.

And if you’re ready to turn an idea into a real product—we welcome you to partner with us. We’ll use our expertise to help you bring your concept to life.

One Response

Do you mind if I quote a few of your articles as long as I provide credit and sources back to your weblog? My blog site is in the exact same niche as yours and my users would definitely benefit from a lot of the information you present here. Please let me know if this alright with you. Thank you!